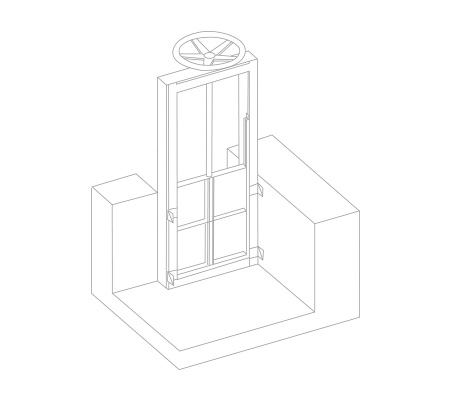

Esareka Penstock / Sluice Gate

More durable

High quality

Custom made

Quick delivery

Good after sales support

ISO Certified

With more than 30 years of specialized experience in full-fletch manufacturing, made to order machine parts, fabrication and sheet metal processing, our factory make use of the latest machinery and the most advanced state-of-art technologies, our clients are assured of the production process.

Using computer technology, we achieve high precision and maximum efficiency in producing quality ESAREKA Penstock / Sluice Gate.

What is Penstock / Sluice Gate ?

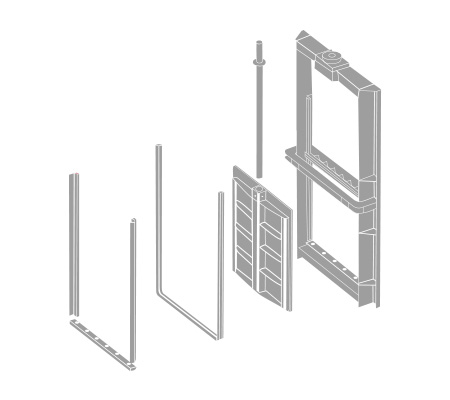

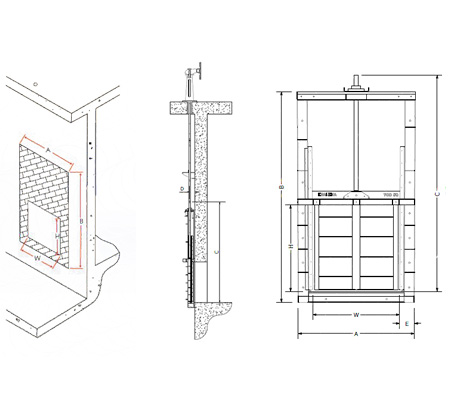

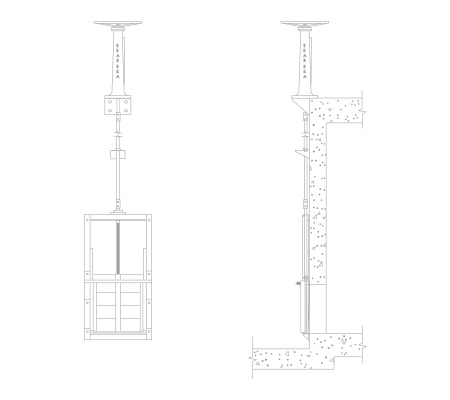

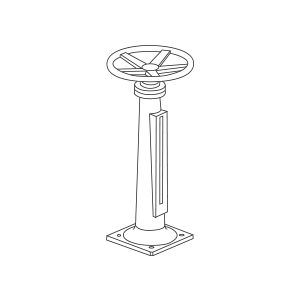

A piece of equipment used to control the flow or level of a liquid consisting a sliding door; controlled by a mechanically operated spindle, moving vertically over the aperture in a frame which is secured on to a structure.

A sluice gate is traditionally a wooden or metal plate which slides in grooves in the sides of channel. Sluice gate are commonly used to control water levels and flow rates in rivers and canals. They are also used in wastewater treatment plants

and to recover minerals in mining operations, and in watermills.

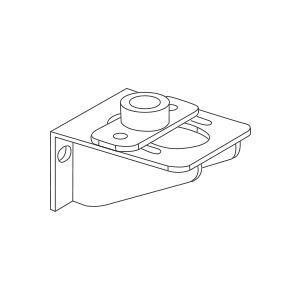

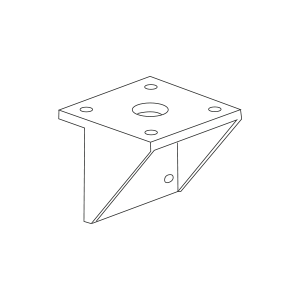

ESAREKA’s SERIES 10 fabricated Penstock / Sluice Gate is a highly versatile flow control gate with various types of mountings.

Adaptable to different applications, the Series 10 can be designed to withstand seheads of up to 18m. When required, the Series 10 can be designed for higher water heads. The seal design keeps the allowable leakage rate to 0.60 l/min per meter of seating perimeter for seating head conditions. The unseating head leakage is 1.25 l/min per meter of perimeter for 6m water head. Over 6m of unseating head, the leakage is corrected at a rate of 0.03 l/min per meter of perimeter for each additional meter over 6m. The leakage rate is 50% of the maximum allowable leakage recommended by AWWA/BS7775.

It is available in sizes from 150mm up to 3000mm. For larger sizes, please contact a Esareka representative. The design is suitable for square, rectangular or round applications.

Because of its stainless steel construction, the SERIES 10 has high corrosion and erosion resistance, and can be operated for many years with a minimum maintenance. Stainless steel provides virtually limitless design flexibility. The result is a lighter weight and easier-to-install gate.